Editors’ Note: Einstein’s Global Diabetes Institute recently joined forces with students at Cooper Union to address the problems faced by amputees in Soroti, Uganda. In this blog post, Meredith Hawkins. M.D., of Einstein and Anita Raja, Ph.D., of Cooper Union explain how their collaboration may improve the lives of diabetes patients in Soroti.

The need for prosthetics in Soroti, Uganda

FIGURE 1

More and more medical professionals and engineers are collaborating to meet the needs of patients globally. Project Kutembea (which means “walking” in Swahili) is the result of a partnership between the Global Diabetes Institute (GDI) at Albert Einstein College of Medicine and the Cooper Union for the Advancement of Science and Art, stemming from a shared goal to help patients at Soroti Regional Referral Hospital in Uganda.

The sheer number of patients who showed up to see the doctors at Soroti Hospital was astonishing. We had heard the statistics before: 422 million cases of diabetes in 2014 and a predicted 592 million cases by 2035, with more than 80 percent of those affected inhabiting low- and middle-income countries. But one morning, nearly 100 people, all of whom were struggling with this disease, came to the clinic. It made the alarming reality of the challenges faced by diabetes patients living in rural Uganda impossible to ignore.

Diabetes is not well recognized in Uganda. In many cases the disease isn’t diagnosed until a serious complication, such as loss of vision or a wound that won’t heal, manifests itself. Furthermore, the lack of resources, including medication, balanced nutrition, and professional medical attention, means that diabetes is often poorly controlled. All these things lead to an extremely high rate of diabetic complications, perhaps the most debilitating of which is lower-limb amputation. At Soroti Hospital, diabetes is the leading cause of amputation.

Quality of life is severely diminished for those individuals who undergo this procedure. Unable to work or manage daily life, many of them suffer serious depression post-amputation. Prosthetic limbs would greatly help, yet the cost of a limb ranges between $250 and $500. This is out of reach for most people in Uganda, as the median income is about $650 per year. The need for an affordable solution was clear.

Thanks to a mutual connection, Einstein and Cooper Union came together and discovered that the GDI’s need for a simple, cost-effective solution to providing support for amputees in Soroti might be met by working with Cooper Union students, who could devise the creative engineering solutions we needed. This student involvement is a logical extension of Einstein students’ contributions of energy and time to the various initiatives that make up the GDI.

The challenge for Cooper students

Project Kutembea is the result of the Cooper Union students rising to the challenge of designing and building a low-cost, below-knee, trans-tibial prosthesis as part of their capstone project in a first-year undergraduate engineering design course.

This mandatory course for all engineering majors gives students a holistic approach to the design process and a broad introduction to the varied skill sets required by effective engineers, while emphasizing the often-conflicting scientific, societal, environmental and sustainable demands. The challenge of building a prosthesis that cost less than $40 and that could withstand rugged terrains and a warm climate was a perfect fit for the course’s project requirements.

Keeping environment and materials in mind

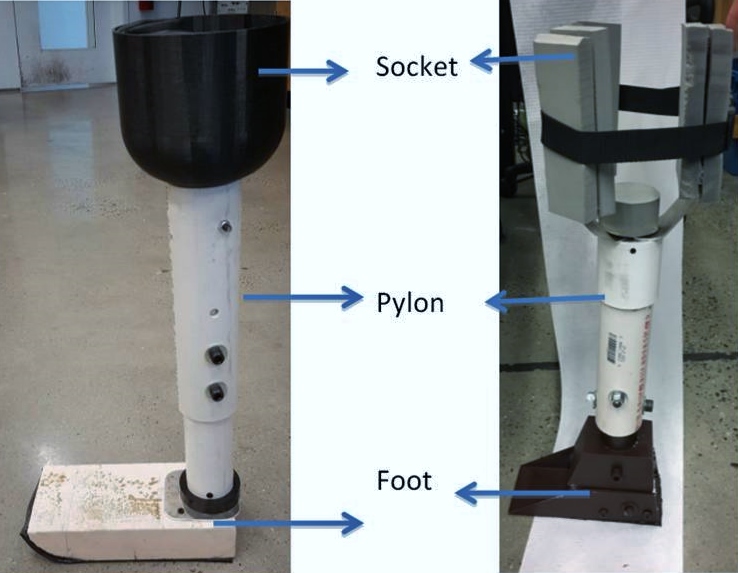

The Cooper-designed prostheses (figure 1) have three parts: the socket that connects the prosthesis to the residual limb, the pylon and the foot. Students focused on three design criteria that would best serve patients at Soroti Hospital: comfort, modularity and adjustability. To achieve comfort, the pylon would fit the residual limb without bruising the stump or causing pain. It would also be lightweight but durable for long-term use in the rural environment of Soroti. Modularity would allow easy and inexpensive replacement of plug-and-use parts; adjustability would let users alter the fit of the prostheses without making expensive trips to the hospital each time.

The materials used in the two prototypes included wood, aluminum, PVC and rubber—all easily available in Soroti, Uganda. The cost for the final version of each prototype, including labor, was less than $30. Both prototypes met the functional and cost goals established at the beginning of the course.

We are now working on a feasibility analysis of both designs. The prototypes will be taken to Soroti by the Einstein team to be evaluated by the Soroti Hospital medical staff and technicians.

Watch the videos below to learn more about Project Kutembea.